|

LUOYANG KAILIN FOUNDRY MATERIAL CO.,LTD

|

High-Aluminum Riser Insulating Service

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

price:lower

quality:high

Means of Transport:Ocean,Air

Packing:1000kgs bag

Brand Name:KailinExpansion: 2~3

Density :1.1g/cm3

Model No.:KL-HA10

We are seeking global co-operation agents for our products.

High-Aluminum Riser Insulating Covering Flux

This covering flux have been proverbially applied in many kinds of iron and steel casting processes,such as ductile iron,cast carbon steel,stainless cast steel,alloyed cast steel,etc..It can significantly reduces riser heat reduction so as to improve cast feeding,and it can cut down the metal consumption as well as to decrease the shrinkage defects of castings.

Features

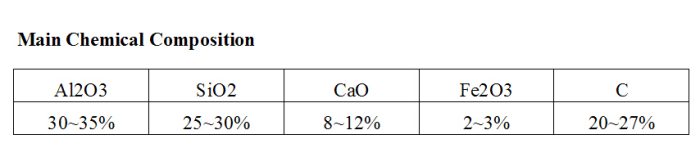

1.Using high-aluminum insulating refractory material,the covering flux has high calorific value and good performance of heat insulation.

2.This covering flux can lead an "U" shape section riser bottom showing that the casting shrinkage has been well compensated.So the foundry can save 30~50% molten steel.

Application Guide

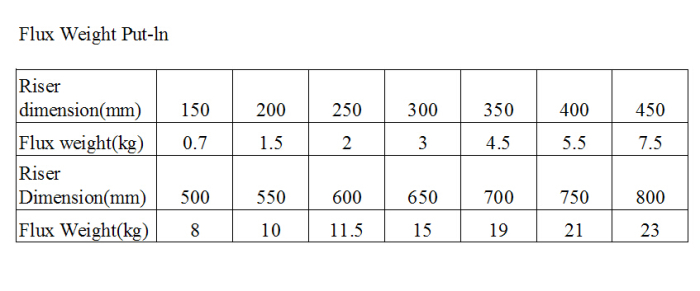

During pouring,when the molten metal rises to more than a half of the riser level,you can put enough amount of covering flux in to the riser cavity.After covering,it's not permitted to pour or light,or the insulating layer would be damaged.

FAQ

Q1:What is the lead time ?

A:Sample is 3~5 days, mass production time is about 10~15days .

Q2.Do you have any MOQ limit?

A:Our MOQ is one container includes 20 tons

Q3:Are you manufactory or trading company?

A:We are manufactory.

Q4: What kind of your products?

A:Our main products is ceramic sand .

Application

Factory Building

Equipment Photo